CKA6136 CNC Horizontal Lathe

1. Machine Application

This machine tool is a CNC horizontal lathe controlled by two coordinates of longitudinal(Z) and horizontal (X), which can machine inside and outside the cylinder, conical surface, circular arc surface, end face, cutting and chamfering of various axial and plate parts automatically and turning metric thread, straight face thread and imperial straight thread and taper thread turning processing.

CKA Series CNC Lathe chooses FANUC, Siemens, Guangzhou CNC system. The workpiece can be loop processed repeatedly.

This kind of machines is suitable for many varieties, medium and small batch production, especially for the complex and high precision parts.

2. Machine Features

Lathe bed is casted using resin sand and artificial aging treatment, therefore, which have good rigidity and shock absorption, and can guarantee the high precision machining;

Manual shift; Electric automatic shiftas optional accessory;

Machine longitudinal and lateral movement axis adopts servo motor drive, high precision ball screw pair, rigid precision composite bearing transmission, and position detection pulse encoder feedback of half closed loop control system. Guide pair adopts international popular high frequency quenching (hard rail) technology and "Plastic sticking”, so, each movement axis response fast, high precision, and long service life;

Equipped with central lubrication device, which can forcefully supply lubrication oil for ball screw and guiderail, and can improve the dynamic response of the machine tool characteristics effectively and the service life of screw guide;

Vertical 4 station toolpost; Horizontal 6 station toolpost as optional accessory;

Standard is manual chuck; Auto chuck is optional accessory;

Manual tailstock; Hydraulic tailstock is optional accessory;

Full cover protection.

3. Specifications

Specifications | CKA6136 |

Max swing diameter over bed | Φ360 mm |

Max swing diameter over toolpost | Φ180 mm |

Max work piece length | 750/1000mm |

Max machining length | 580/830mm |

Max turning diameter | Vertical 4 station | Φ360 mm |

Horizontal 6 station toolpost | Φ300 mm |

Spindle center height | 186 mm |

Bed guide way width | 300 mm |

Standard configuration |

Double speed motor drive | Manual 3 shifts |

Main motor | 3/4.5Kw |

Spindle hole diameter | Φ48 mm |

Spindle head | ISO A2-6 |

Spindle front end bearing inner diameter | Φ 90mm |

Spindle speed | 32-2000 r/min |

Optional configuration |

Frequency + Manual 3 shifts | Stepless speed |

Main motor | 5.5kW |

Spindle hole diameter | Φ52 mm |

Spindle head | ISO A2-6 |

Spindle front end bearing inner diameter | Φ90mm |

Spindle speed | 20-2500 r/min |

Tailstock sleeve diameter | Φ63mm |

Tailstock sleeve travel | Manual | 130 mm |

Hydraulic | 120 mm |

Tailstock sleeve taper degree | Morse 4# |

Max travel of toolpost | Horizontal (X) | 230 mm |

Vertical (Z) | 580/830mm |

Diameter*pitch of ball screw | Horizontal (X) | φ20×5mm |

Vertical (Z) | Φ32×5mm (750-1500mm) |

Cutting force | Horizontal (X) | 2500 N |

Vertical (Z) | 5000 N |

Rapid feeding | Horizontal (X) | 4000mm/min |

Vertical (Z) | 500mm/min |

Cutting feed range | Mm/r | 0.01-500 |

Location accuracy | Horizontal (X) | 0.018 mm |

Vertical (Z) | 0.021mm (>500~800) 0.024 (>800~1250) |

Repeatability accuracy | Horizontal (X) | 0.006 mm |

Vertical (Z) | 0.008mm (>500~800) 0.011 (>800~1250) |

Workpiece processing accuracy | IT6~ IT7 |

Roughness of the workpiece surface | Ra1.6 |

Electrical vertical 4 station toolpost | Tool post motor | Power | 90 W |

Speed | 1400 r/min |

Tool section | 20×20 mm |

Repeatability accuracy | 0.008 mm |

Optional Accessory Horizontal 6 station toolpost (Optional) | Tool post motor | Power | 120 W |

Speed | 1400 r/min |

Tool section | 20×20 mm |

Repeatability accuracy | 0.008 mm |

Power supply | AC 3 Phase/380 V±10% /50Hz±2Hz |

Capacity of power use | 16KVA |

Coolant tank volume | 20L |

Coolant pump motor power | 200 W |

Coolant flow | 25 L/min |

Machine size(L*W*H) | 2300×1480×1520mm (750mm) |

2550×1480×1520mm (1000mm) |

Machine packing size(L*W*H) | 2500×1750×1950mm (750mm) |

2750×1750×1950mm (1000mm) |

Machine net weight | 1800 kg (750mm) |

1950 kg (1000mm) |

4. Optional Accessory List

No | Name | Specifications | Qty |

1 | 4-jaw chuck |

| Ф250 | 1 group |

2 | Hydraulic chuck |

|

| 1 group |

3 | Steady rest | MB36-64 | Ф12~Ф100 | 1 group |

4 | Live Center | DB1222 | D414 | 1 group |

5 | Follow rest | MB36~65 | Ф20~Ф90 | 1 group |

6 | Center Sleeve | DB1220 | 6/4 | 1 piece |

7 | Center | GB9204 | DM114 | 2 piece |

8 | Bolts | GB799 | MA16×300 | 6 pieces |

9 | Nuts | GB6170 | M16 | 6 pieces |

No | Items | Chuck model | Cylinder model | Pull rod hole |

1 | Taiwan solid chuck | V-208A6 | MH125 | ---- |

2 | Taiwan hollow chuck | N-208A6 | M1552 | φ32 |

3 | Chinese brand solid chuck | K51200 | P22125 | ---- |

4 | Chinese brand hollow chuck | K52200 | P23125 | φ32 |

Controller (Choose one) | Main motor | X/Z axis motor |

FANUC 0i-TF(5) | Double speed motor Frequency variable motor Servo motor (Choose one) | 7 Nm / 7Nm/1.2kW/2000/3000 |

Siemens 808D/828D | 6Nm / 6Nm/1.2kW/1.5kW/2000/3000 |

GSK 980T | 5 Nm / 7.5 Nm/1.3kW/1.88Kw/2000/2000 |

Huazhong 808T | 4.8 Nm/ 7.2 Nm/1kW/1.5kW/2000/2000 |

5. Main Purchasing ComponentsList

NO | ITEMS | MANUFACTURER |

1 | Spindle bearings | Harbin Bearing Co., Ltd. |

2 | Main transmission triangle belt | Domestic famous brand |

3 | X/Z axis ball screw | HPS |

4 | Screw bearings | Domestic famous brand |

5 | Synchronous toothed belt and pulley | Ningbo synchronous belt factory |

6 | Vertical 4 station toolpost | Wang Fangdian Accessories Factory |

7 | Manual chuck | Wang Fangdian Accessories Factory |

8 | Chain | Anji Chain Co. |

9 | Centralized lubrication | Taiwan |

10 | Controller | FANUC |

11 | Electronic component | Domestic famous brand |

12 | Double speed motor | Domestic famous brand |

13 | Safety lock | Domestic famous brand |

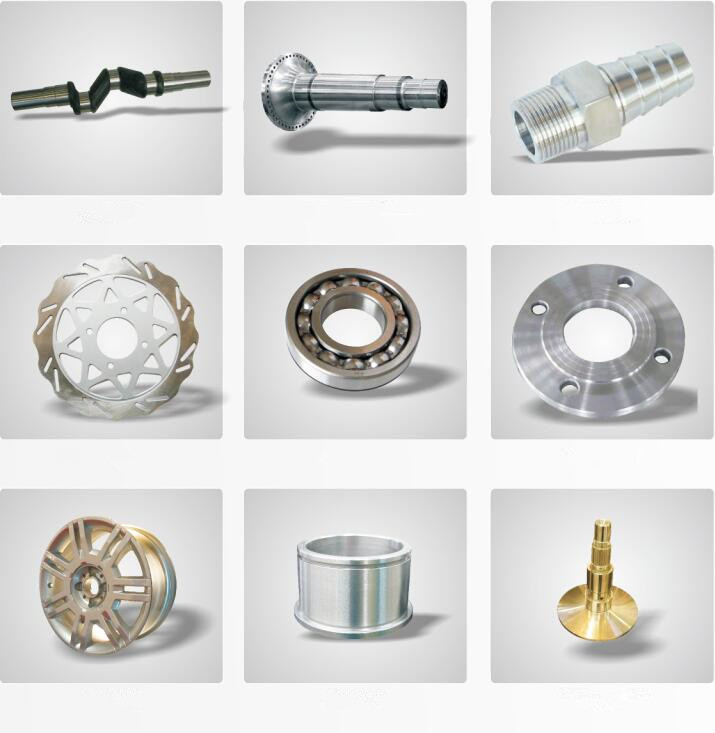

6. Machine Detailed Photos